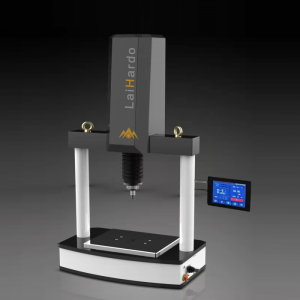

HBRVT-187.5 Computerised Digital Universal Hardness Tester yeKombuta

*HBRVS-187.5T Digital Brinell Rockwell & Vickers hardness tester ine skrini hombe itsva yakagadzirwa ine kuvimbika kwakanaka, kushanda kwakanaka uye kutarisa kuri nyore, saka chigadzirwa chemhando yepamusoro chinosanganisa maficha e optic, mechanic uye emagetsi.

*Ine nzira nhatu dzekuyedza dzeBrinell, Rockwell naVickers uye mazinga manomwe esimba rekuyedza, izvo zvinogona kuyedza mhando dzakasiyana dzehukukutu.

*Kuedza kurodha, kudzika, kuburitsa zvinhu zvinotora otomatiki kuti zvive nyore uye nekukurumidza kushanda.

*Inogona kuratidza nekuisa chiyero chiripo, simba rekuyedza, chiyero chekuyedza, nguva yekugara uye kushandurwa kwekuomarara;

*Basa guru nderinotevera: Kusarudzwa kweBrinell, Rockwell naVickers nzira nhatu dzekuyedza; Zviyero zvekushandura zvemhando dzakasiyana dzekuoma; Mhedzisiro yekuyedza inogona kuchengetwa kuti iongororwe kana kudhindwa, kuverengerwa otomatiki kwehuwandu hwepamusoro, hushoma uye hwepakati; Iine RS232 interface yekubatanidza kukombiyuta.

Yakakodzera simbi yakaoma uye yakaomeswa pamusoro, simbi yakaoma alloy, zvikamu zvekukanda, simbi dzisina feri, mhando dzakasiyana dzesimbi inoomesa uye inodziya uye simbi inodziya, simbi yakakangwa, simbi dzakapfava, mishonga yekurapa kupisa pamusoro uye mishonga yekurapa makemikari nezvimwewo.

Simba rekuyedza reRockwell: 60kgf (588.4N), 100kgf (980.7N), 150kgf (1471N)

Simba rekuyedza reBrinell: 30kgf (294.2N), 31.25kgf (306.5N), 62.5kgf (612.9N), 100kgf (980.7N), 187.5kgf (1839N)

Simba rekuyedza reVickers: 30kgf (294.2N), 100kgf (980.7N) Indenter:

Diamond Rockwell Indenter, Diamond Vickers Indenter,

Kuverenga kweBall Indenter Hardness ф1.588mm, ф2.5mm, ф5mm: Kubata Screen Display

Chiyero cheKuedza: HRA, HRB, HRC, HRD, HBW1/30, HBW2.5/31.25, HBW2.5/62.5, HBW2.5/187.5, HBW5/62.5, HBW10/100, HV30, HV100

Shanduko Chikero: HRA, HRB, HRC, HRD, HRE, HRF, HRG, HRK, HR15N, HR30N, HR45N, HR15T, HR30T, HR45T,

Kukura: Brinell: 37.5×, Vickers: 75×

Chiyero cheKuyera cheChidiki: Brinell: 0.5μm, Vickers: 0.25μm

Kuomarara Kugadziriswa: Rockwell: 0.1HR, Brinell: 0.1HBW, Vickers: 0.1HV

Nguva Yokugara: 0 ~ masekondi 60

Kureba Kwakakura kweMuenzaniso:

Rockwell: 230mm, Brinell: 150mm, Vickers: 165mm,

Huro: 165mm

Data Output:Yakavakwa-mukati Printer,RS232 Interface

Simba remagetsi: AC220V,50Hz

Ita Standard:

ISO 6508,ASTM E18,JIS Z2245,GB/T 230.2 ISO 6506,ASTM E10,JIS Z2243,GB/T 231.2 ISO 6507,ASTM E92,JIS Z2244,GB/T 4340.2

Saizi: 475×200×700mm,

Huremu Hwakachena: 70kg, Huremu Hwakazara: 90kg

| Zita | Huwandu | Zita | Huwandu |

| Muviri Mukuru weChishandiso | Seti imwe chete | Diamond Rockwell Indenter | 1 chikamu |

| Dhaimani Vickers Indenter | 1 chikamu | ф1.588mm, ф2.5mm, ф5mm Bhora Rinoyerera | imwe neimwe 1 pc |

| Tafura Yekuyedza Yakatsvedza | 1 chikamu | Tafura Yekuyedza Yepakati Pendege | 1 chikamu |

| Tafura Yekuyedza Ndege Yakakura | 1 chikamu | Tafura Yekuyedza Yakaita seV | 1 chikamu |

| 15× Dhijitari Yekuyera Ziso | 1 chikamu | 2.5×, 5× Chinangwa | imwe neimwe 1 pc |

| Sisitimu yeMaikorosikopu (inosanganisira chiedza chemukati nechiedza chekunze) | Seti imwe chete | Chivharo Chekuoma 150~250 HB W 2.5/187.5 | 1 chikamu |

| Kuomarara Chivharo 60~70 HRC | 1 chikamu | Kuomarara Chivharo 20~30 HRC | 1 chikamu |

| Kuomarara Chivharo 80~100 HRB | 1 chikamu | Chivharo Chekuoma 700~800 HV 30 | 1 chikamu |

| Sisitimu yekuyera mifananidzo yeCCD | Seti imwe chete | Waya yemagetsi | 1 chikamu |

| Bhuku reMirayiridzo yekushandisa | Kopi imwe chete | Komputa (Sarudzo) | 1 chikamu |

| Chitupa | Kopi imwe chete | Chifukidziro chekudzivirira guruva | 1 chikamu |

Vickers:

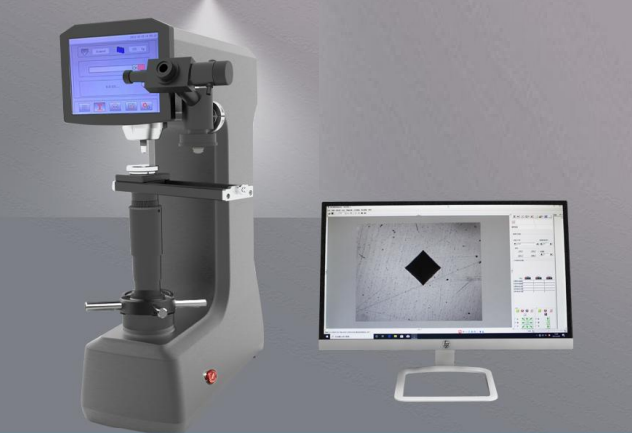

* Sisitimu yekugadzirisa mifananidzo yeCCD inogona kupedzisa maitiro otomatiki: kuyerwa kwehurefu hwe diagonal hwekudzika, kuratidzwa kwehukuru hwekuoma, kuyedzwa kwedata uye kuchengetedza mifananidzo, nezvimwewo.

* Inowanikwa kuti igadzirise muganho wepamusoro nepasi wekuoma, mhedzisiro yekuyedza inogona kuongororwa kana yakagadziridzwa otomatiki.

* Enderera mberi nekuyedza kuomarara pamapoinzi makumi maviri ekuyedza panguva imwe chete (sarudza daro riri pakati pepoinzi dzekuyedza sezvaunoda), uye chengeta zvabuda mukuyedza seboka rimwe chete.

* Kuchinja pakati pemhando dzakasiyana dzehukukutu uye simba rekusimba

* Bvunza data rakachengetedzwa nemufananidzo chero nguva

* Mutengi anogona kugadzirisa kururama kwehuwandu hwekuoma kwakayerwa chero nguva zvichienderana nekuenzanisa kweHardness Tester

* HV yakayerwa inogona kuchinjwa kuita mamwe ma hardness scales (HB,HRetc)

* Sisitimu inopa maturusi akawanda ekugadzirisa mifananidzo kune vashandisi vepamusoro. Maturusi akajairwa musisitimu anosanganisira kugadzirisa Brightness, Contrast, Gamma, uye Histogram Level, uye mabasa eSharpen, Smooth, Invert, uye Convert kuita Grey. Pamifananidzo yegrey scale, sisitimu inopa maturusi akasiyana-siyana epamusoro mukuseta nekutsvaga mipendero, pamwe nemamwe maturusi akajairwa mumabasa e morphological akadai se Open, Close, Dilation, Erosion, Skeletonize, uye Flood Fill nezvimwewo.

* Sisitimu inopa maturusi ekudhirowa nekuyera maumbirwo akafanana ejometri akadai semitsetse, maangles ane mapoinzi mana (ema vertex asipo kana akavanzwa), ma ractangles, madenderedzwa, ma ellipses, uye ma polygons. Ziva kuti chiyero chinofungidzira kuti sisitimu yakayerwa.

* Sisitimu inobvumira mushandisi kutarisira mifananidzo yakawanda mualbum iyo inogona kuchengetwa uye kuvhurwa kubva kufaira realbum. Mifananidzo inogona kuva nemaumbirwo akajairwa ejometri uye magwaro sezvakaiswa nemushandisi sezvakatsanangurwa pamusoro apa.

Pamufananidzo, sisitimu inopa mugadziri wemagwaro kuti aise/agadzirise magwaro ane zviri mukati zviri nyore kana kuti mufomati yepamusoro yeHTML ine zvinhu zvinosanganisira matabhesi, runyorwa, uye mifananidzo.

*Sisitimu inogona kudhinda mufananidzo nehukuru hwakatarwa nemushandisi kana yakaongororwa.

Inogona kushandiswa kuona kuomarara kwesimbi yeVickers, simbi dzisina ferrous, ceramics, simbi dzakagadziriswa pamusoro, uye kuomarara kwesimbi dzakakangwa, dzakaiswa nitride uye dzakaomarara. Zvakakodzerawo kuona kuomarara kwesimbi dzeVickers kwezvikamu zvidiki nezvitete.

Brinell:

1. Kuyera otomatiki: Tora otomatiki kupinda kwechinhu woyera dhayamita woverenga kukosha kwakakodzera kwekuoma kweBrinell;

2. Kuyera nemaoko: Kuyera nemaoko indentation, sisitimu inoverenga kukosha kwakakodzera kwekuoma kweBrinell;

3. Kuchinja kuomarara: Sisitimu iyi inogona kushandura kukosha kwekuomarara kweBrinell kwakayerwa HB kuita kumwe kukosha kwekuomarara kwakadai seHV, HR nezvimwewo;

4. Nhamba dzedata: Sisitimu inogona kuverenga otomatiki kukosha kweavhareji, musiyano uye humwe huwandu hwenhamba hwekuoma;

5. Alarm inodarika yakajairika: Isa otomatiki chiratidzo chisina kujairika, kana kuomarara kwacho kuchidarika kukosha kwakataurwa, zvinongoerekana zvaita alarm;

6. Mushumo wekuyedza: Gadzira otomatiki mushumo wefomati yeWORD, matemplate emushumo anogona kuchinjwa nemushandisi.

7. Kuchengetedzwa kwedata: Data rekuyera kusanganisira mufananidzo wekudzika kwedata rinogona kuchengetwa mufaira.

8. Mamwe mabasa: anosanganisira mabasa ese ekugadzirisa mifananidzo uye masisitimu ekuyera, akadai sekutora mifananidzo, kugadzirisa, kugadzirisa mifananidzo, kuyerwa kwejometri, kutsanangura, manejimendi yemifananidzo uye nguva dzakatarwa dzakadhindwa nezvimwewo.