Maikorosikopu yesimbi yakatwasuka yeLHMICV5100 inongoerekana yaita otomatiki

Mabasa ese akagadzirwa zvichienderana nemutemo we ergonomic kuderedza kuneta kwemushandisi. Dhizaini yayo yezvikamu zve modular inobvumira musanganiswa unochinjika wemabasa esystem. Inosanganisira mabasa akasiyana-siyana ekutarisa, anosanganisira bright-field, dark-field, oblique illumination, polarized light, uye DIC differential interferometry, nemabasa anosarudzwa zvichienderana nemashandisirwo chaiwo.

Inotsigira nzvimbo yekuona ye25mm inotungamira pasi rose, ichikupa ruzivo rutsva rwekuona kwakafara. Kugadziriswa kwe diopter kwakakura kunogona kusangana nezvinodiwa nevashandisi vakawanda pamapurogiramu chaiwo.

Zvinangwa zve semi-apochromatic zve bright-field ne dark-field zvakagadzirwa nema lenzi akasarudzwa zvakanaka-transmittance uye tekinoroji yepamusoro ye coating kuti ibudise mavara echisikigo emuenzaniso; dhizaini ye semi-apochromatic ine kugona kwakanaka kwekugadzirisa mavara, zvichivandudza kusiyana uye kujeka kwemufananidzo wakaonekwa.

Sisitimu ye polarization inosanganisira polarizer insert uye analyzer insert, iyo inogona kuona polarized light. Mukuongorora kwe semiconductor nePCB, inogona kubvisa stray light uye kuita kuti zvinhu zvive pachena.

Chinoongorora chinotenderera che360° chinoita kuti zvive nyore kuona chitarisiko chemuenzaniso pasi pechiedza nemakona akasiyana-siyana epolarization pasina kufambisa muenzaniso.

● Danho reXY rine mota yakanyatsogadzirwa, pamwe chete nehurongwa hwekudzora hurefu hwakavharwa, rinogonesa kuongorora mifananidzo yakakura uye kugadzira mifananidzo inoshanda zvakanyanya, zvichiita kuti pave nekubatanidzwa kwakanaka kwenzvimbo dzakawanda dzekuona.

● Inotsigira nzira dzekuskena dzakagadzirirwa iwe, inochinjika kumasampuli asina kurongeka, uye inovandudza mwero wekubudirira kwekubatanidza nzvimbo dzakaoma.

●Z-axis inofambiswa nemagetsi, zvichiita kuti mufananidzo utaridzike otomatiki.

Chinobatidza chiri pamberi pechiedza chinoita kuti kuchinjana pakati peminda yakajeka neyakasviba kuve nyore uye chine basa rekubatanidza firita isina kusimba. Izvi zvinodzivirira maziso emushandisi kuti asakurumidzirwe nechiedza chakasimba paanochinja kubva kuminda yakasviba kuenda kuminda yakajeka, zvichivandudza kugadzikana kwemushandisi.

Chinoshandura zvinhu zvine maburi akawanda chinobvumira kuti pave nekutarisa kwakaringana uye kunogara kuripo pakukura kwakaderera, kwepakati, uye kwepamusoro kwemuenzaniso mumwe chete panzvimbo dzakasiyana dzekutarisa.

| Sisitimu yemaziso | Sisitimu yemaziso yakagadziriswa isingaverengeki |

| Chubhu yekutarisa | 30° kutsveyama, chubhu yekutarisa ine nzira nhatu isina muganho, kugadzirisa daro pakati pevana: 50mm~76mm, chiyero chekupatsanura danda remabhora maviri, binocular:trino = 100:0 kana 0:100 |

| chishongo cheziso | Chiso chepamusoro, PL10X / 25mm, diopter inogadzirisika. |

| Minda yakajeka nerimaLenzi ine chinangwa chakaoma kunzwisisa | LMPLFL 5X /0.15 BD DIC WD13.5mmLMPLFL10X/0.30 BD DIC WD9.0mmLMPLFL20X/0.5 BD DIC WD2.5mmLMPLFL50X/0.80 BD WD1.0mmLMPLFL100X / 0.90 BD WD 1.0mm |

| chishanduri | Chinoshandura maburi matanhatu cheminda yakajeka neyakasviba, chine nzvimbo yeDIC |

| furemu | Kamera ine furemu yekuratidza uye nzira yakaderera yekubatanidza zvinhu ne coaxial coarse uye fine focus. Kufamba kwekugadzirisa zvinhu ne coarse 25mm, uye kunyatsogadzirisa zvinhu ne fine configuration kuri 0.001mm. Inosanganisira mudziyo we anti-slip adjustment tension uye random upper limit switch. |

| Sisitimu yemwenje | Chiedza chinopenya chemunda wakajeka uye werima chine diaphragm inoshanduka-shanduka, diaphragm yemunda, uye chinogadziriswa pakati; chine mudziyo wekuchinja chiedza chemunda wakajeka uye werima; chine nzvimbo yekusefa mavara uye nzvimbo yekuyera polarizer/analyzer. |

| imba yerambi | Kamuri remarambi re12V 100W halogen, rakakodzera kutumirwa uye kuratidzwa, rinowanikwa kuti riodwe pachine nguva. |

| Z-axis | Kutarisisa otomatiki |

| Puratifomu yemagetsi | Kufamba kwepuratifomu: Kutungamira kwakatwasuka * Kutungamira kwakatwasuka = 80 * 60 (yuniti: mm)Mutobvu wescrew: 2000μmKururama kweXY kudzokorora: mukati me ± 2 μmKudzokororwa kweZ-axis: mukati me ± 1 μmKugadziriswa pazvikamu gumi nematanhatu: 0.625μm padanho rimwe nerimwe Kona yedanho remota yestepper: 1.8° Rated operating current: 1.0A pa shaft (inofambiswa ne24V) Mutoro wepamusoro: ≥5kg Nzvimbo yepamusoro yekusvika parwendo rwekuenda nekudzoka: 2 micrometer Kureba kwakanyanya kwemuenzaniso i25mm (humwe hurefu hunogona kugadziriswa). |

| Bhokisi rekudzora dhiraivha | Inoshandisa RS232 serial port yakajairwa kutaurirana nePC (115200 baud rate).Kudzora chiteshi chemotokari kuburikidza neserial kunobvumira kutara kumhanya kwemota, daro, uye gwara rekufamba. |

| Zvimwe zvakabatanidzwa | Polarizer insert, 360° rotating analyzer insert, uye interference filter yakagadzirirwa kufungisisa. |

| Sisitimu Yekuongorora | FMIA 2025 software chaiyo yekuongorora metallographic uye porosity software |

| mudziyo wekamera | 5 megapixels, 36 fps |

| 0.5X adapter lenzi interface, micrometer | |

| Makomputa ekudzora maindasitiri | Intel i5 processor, 64GB RAM, 1TB SSD, 27-inch 4K monitor |

Software yedu yekuongorora mifananidzo yesimbi isystem itsva yakagadzirwa nekambani yedu zvichibva pane zvinodiwa pakuongorora metallographic zvemakambani ekugadzira zvinhu, makambani ezvikamu zvemotokari, makambani ekurapa kupisa, indasitiri yesimbi, indasitiri yemagetsi, indasitiri yezvikamu zvechitima, uye makambani akasiyana-siyana ekuongorora ane chekuita nazvo. Kuti tivandudze huwandu hwechigadzirwa uye tibatsire kuvandudza mwero wekuongororwa kwema laboratori akasiyana-siyana, takaunganidza zvinodiwa nepfungwa dzenyanzvi nevadzidzisi vanobva kumaindasitiri akasiyana-siyana.

Software yekuongorora mifananidzo yesimbi yakagadziriswazve uye yakagadziridzwa zvizere. Sisitimu iyi inofukidza huwandu hwakawanda hwemiyero yekuyedza metallographic yemuno neyekunze, inobatanidza ongororo yehuwandu uye yemhando, uye inowedzera kuumbwa kwemukati memunda uye mabasa ekusona mifananidzo. Iyo interface iri nyore uye inogona kutora mifananidzo yakawanda-ye-nzvimbo-ye-maonero yekurongeka kwemifananidzo uye kuongorora. Kushanda kwayo kuri nyore, kubvisa matanho akasiyana-siyana akaomarara esoftware yekare, zvichiita kuti kuyedza kukurumidze uye kushande.

Tagadzira sisitimu itsva yekuongorora metallographic "yehunyanzvi, yakarurama, uye inoshanda" kuti tiite kuti kuongorora metallographic kuve nyore.

Raibhurari yenyika yesoftware system ine mazana emapoka, anosanganisira zviyero zvemetallographic zvinoshandiswa zvakanyanya uye anosangana nezvinodiwa zvekuongorora metallographic nekuyedza zvemasangano mazhinji. Mapoka akakodzera anotsanangurwa uye anovhurwa zvichienderana nezvinodiwa nemaindasitiri akasiyana kuti asvike pazvinodiwa zvekuyedza maindasitiri. Mamodule ese anowanikwa mahara kwehupenyu hwese, uye zviyero zvinovandudzwa mahara kwehupenyu hwese.

Zvichienderana nekuwedzera kwehuwandu hwezvinhu zvitsva uye mamakisi anounzwa kunze kwenyika, zvinhu uye mwero wekuongorora usati waiswa musoftware zvinogona kugadziriswa uye kuiswa zvakasiyana.

Zvakanakira uye mabasayesoftware yekuongorora metallographic:

- Kutora uye kutora mifananidzo yemavhidhiyo akawanda: Kupfura ma batch, kutumidza mazita ema batch, kuchengetedza ma batch, kudhinda ma batch ne fixed magnification uye mamwe mabasa ekugadzirisa ma batch akawanda anoita kuti maitiro ekuongorora ma batch sample ave nyore uye anoshanda.

- Yepamusoromarongero ekamera:Nguva yekuratidzwa, kuwedzera, kupinza, kuwanda, gamma, kusiyana, kupenya, kuyera kwakachena, dema, uye mamwe marongero ebasa.

- Dzvanya kamwe cheteKuenzanisa zvinangwa zvese:Basa rekugadzirisa rakagadziridzwa zvizere, zvichikubvumidza kuti upedze kugadzirisa ma parameter ese ekutarisa nekudzvanya kamwe chete. Kana tichienzanisa nenzira yekutanga yekugadzirisa, nzira itsva yekugadzirisa iri nyore uye inokurumidza kushanda.

- Mabasa ekugadzirisa mifananidzo:kupatsanurwa kwemavara, kushandurwa kwegrayscale, thresholding, binarization, kuvandudzwa kwemufananidzo, phase inversion, sharpening, scratch and smudge removal, image histogram, nezvimwewo.

- Kubuda kwemifananidzo:Zvinhu zvinosanganisira kudhinda mifananidzo yakawanda, mazita emifananidzo akagadzirwa, marongero ema parameter ekuyera, kutumira kunze kuPDF/Word/Excel, uye preview yekudhinda.

Kuyera uye kuchengetedza mufananidzo:Zvishandiso zvakasiyana-siyana zvekuyera zviripo (zvinosanganisira daro, kona, kona pakati pemitsara miviri, rectangle, daro repoint-to-line, ellipse, polygon, parallel line distance, three-point arc, three-point denderedzwa, nezvimwewo), zvichibvumira kudhirowa miseve, kunyora mazita, uye kuwedzera...Sarudzo dzakawanda dziripo dzemitsara inobatsira, hupamhi hwemutsara, uye mayuniti ekureba; ruvara rwefonti yekuyera, saizi, uye maitiro efonti zviripowo; data rekuyedza rinogona kupfupikiswa uye kutumirwa kuExcel.

Basa rekuongorora sangano:Raibhurari yesoftware ine mhando dzakasiyana-siyana dzemiyero yekuyedza, kusanganisira GB/ASTM/ISO/DIN/QC/JB/DL/TB/SS nedzimwe nzira dzekuongorora sangano. Mitemo iri muraibhurari yesoftware inogona kuvandudzwa mahara, uye software ine kugona kwekuongorora otomatiki uye kuenzanisa. Ine mabasa matatu ekuongorora metallographic: yekutanga, yechipiri, uye inobatsirwa. Iri nyore, iri nyore, uye inokurumidza kushandisa, uye inopa zviyero zvakarurama uye zvakavimbika.

Zvinhu zvepamusoro zvekugadzirisa:Kudzora nhanho dzemaikorosikopu nemota, kugadzirisa mifananidzo, kugadzira mepu yechiedza che3D, dhatabhesi yemifananidzo, nezvimwewo.

Matemplate akasiyana-siyana emishumo:Inogadzira otomatiki mishumo yekuongorora metallographic ine mifananidzo yakawanda, ine sarudzo dzemaitiro emishumo yemodule imwe chete kana multi-module. Matemplate emishumo anogona kuchinjwa kuti asanganise malogo ekambani, mazita emakambani, maitiro ekuyedza, uye rumwe ruzivo. Matemplate emishumo yakagadzirirwa anowanikwawo kuti aenderane nezvaunoda chaizvo.

Basa rekuongorora tissue rinofambiswa neAI:Module yekuongorora matishu eAI inogadziriswa inoshandisa hungwaru hwekugadzira kuti ipedzise kuongorora nekuona magadzirirwo ese ezviro, ichiona nekuongorora magadzirirwo ezviro otomatiki. Maitiro ekushanda ari nyore, achideredza simba revashandi. Kuvandudza kushanda kwekuyedza zvinhu.

Raibhurari yeNyika Yekudhirowa Yakajairika:Ine mazana emifananidzo yenyika kuti vatengi vadzidze uye vatarise.

Module Yekudzidzisa yeMetallography:Inosanganisira module yekudzidzisa metallography kuti vatengi vadzidze uye vataure nezvayo.

Basa rekuwedzera munda reEDF Depth of Field:Kune mienzaniso isina kuenzana uye isingakwanise kurongeka, software iyi inopa basa rekushandura EDF. Nekugadzirisa vhiri reZ-axis micro-adjustment focusing re microscope, ruzivo rwakajeka mumuenzaniso rucharamba ruchiwedzerwa kuhwindo rekushandura EDF kuti riwedzere kushanduka. Software iyi inorekodha otomatiki mifananidzo yakajeka pakadzika kwakasiyana kwemunda uye inoibatanidza kuita mufananidzo wakajeka.

Basa rekusona mufananidzo:Kune vatengi vanoda kuongorora nzvimbo yakakura yekuona, software iyi inopa basa rekusona mufananidzo. Vashandisi vanogona kufambisa puratifomu yeXY yemaikorosikopu kuti vakwanise kuongorora mifananidzo zvizere uye kugadzira mifananidzo inoshanda zvakanyanya kuti vave nechokwadi chekuti nzvimbo dzakawanda dzekuona dzakabatana zvakanaka. Izvi zvinozadzisa zvinodiwa nemutengi zvekutora mifananidzo yenzvimbo huru dzekuona uye zvinogadzirisa kunyara kwekusakwanisa kutora mifananidzo nekuda kwenzvimbo isina kukwana yekuona maikorosikopu.

Inotsigira nzira dzekuskena dzakagadzirirwa iwe, inochinjika kumasampuli asina kurongeka, uye inovandudza mwero wekubudirira kwekubatanidza nzvimbo dzakaoma.

Z-axis inofambiswa nemagetsi, zvichiita kuti mufananidzo utaridzike otomatiki.

| GB/T 10561-2023 Kusarudza Kwezvinhu Zvisiri zvesimbi Zviri Musimbi | GB/T 34474.1-2017 Kuongorora chimiro chakabatanidzwa musimbi |

| GB/T 7216-2023 Kuongorora Metallographic yeGrey Cast Iron | DL/T 773-2016 Spheroidization Rating Standard yeSimbi ye12Cr1MoV Inoshandiswa Mumapurazi Emagetsi Anodziya |

| GB / T 26656 - 2023 Kuongorora Metallographic yeVermicular Graphite Cast Iron | DL / T 1422 - 2015 18Cr-8Ni Series Austenitic Stainless Steel Boiler Tube Microstructure Kuyera Kukwegura Kwechinyakare |

| GB/T 13299-2022 Nzira Yekuongorora Yekuvaka Simbi Yemhando Yediki | GB /T 3489-2015 Masimbi akaomarara - Kuongororwa kweMetallographic kwe porosity uye kabhoni isina kusanganiswa |

| GB/T 9441-2021 Kuongorora kwesimbi yesimbi yesimbi yesimbi | JB/T 1255-2014 Mamiriro Ehunyanzvi Ekurapa Kupisa Kwezvikamu zveSimbi Zvinotakura Kabhoni Yakawanda zveChromium zveRolling Bearings |

| GB/T 38720-2020 Kuongorora Metallographic yeSimbi yeKabhoni Yakadzimwa uye Simbi yeKabhoni Yakasanganiswa neAlloy yeKabhoni Yakasanganiswa | GB / T 1299 - 2014 Chishandiso neSimbi Inofa |

| GB/T 224-2019 Nzira yekuona Kudzika kweLayer Yakabviswa Kabhoni muSimbi | GB / T 25744 - 2010 Kuongorora Metallographic kweZvikamu zveSimbi Yakakangwa, Yakadzimwa, uye Yakanyoroveswa |

| TB/T 2942.2-2018 ZG230-450 Kuongorora Simbi Yakagadzirwa Nesimbi | GB/T13305-2008 Kuongororwa kweMetallographic kwehuwandu hwenzvimbo yeα-phase musimbi isina ngura |

| JB/T 5108-2018 Kuongororwa kweMetallographic yeBrass Yakakandwa | JB/T 9204-2008 Kuongorora Metallographic kweZvikamu zveSimbi Zvakaomeswa zveInduction |

| GB /T 6394-2017 Nzira yekuona Avhareji yeSaizi yeSimbi | GB/T 13320-2007 Zvishandiso zvesimbi, madhayagiramu ekuyera chimiro chesimbi uye nzira dzekuongorora |

| JB/T7946.1-2017 Metallography yeCast Aluminum Alloys | DL/T 999-2006 Spheroidized Steel Rating Standard yeMagetsi Emagetsi |

| JB/T7946.2-2017 Kupisa Kwakapfurikidza kweCast Aluminum-Silicon Alloys | DL/T 439-2006 Nhungamiro dzeUnyanzvi dzeZvisungo zveKupisa Kwakanyanya muZvivako zveMagetsi eKupisa |

| JB/T7946.3-2017 Kandai Aruminiyamu Alloy Pinhole | DL/T 786-2001 Standard yeKuedza uye Kuyera Graphitization yeCarbon Steel |

| JB/T 7946.4-2017 Metallography yeAluminium Alloys Yakakandwa | B/T 1979-2001 Dhayagiramu yekuyera zvikanganiso zvemaumbirwo esimbi yekuvaka ine kukura kwakaderera |

| GB / T 34891 - 2017 Rolling Bearings_Mamiriro Ehunyanzvi Ekurapa Kupisa kweZvikamu zveSimbi Zvinotakura Kabhoni Yakawanda yeChromium | DL/T 674-1999 Standard yePearlite Spheroidization Rating yeNhamba 20 yeSimbi yeMagetsi eThermal |

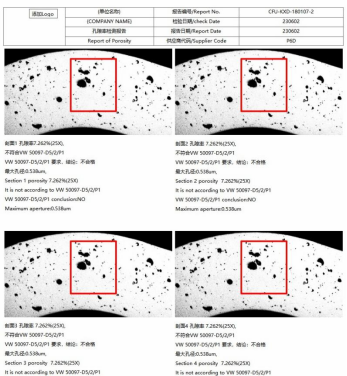

Sisitimu yekuongorora mifananidzo yeFKX2025 porosity inoshandisa microscopic imaging kuti ione porosity yezvikamu zvemotokari. Iyi sisitimu yekuyera porosity ye cast aluminum inoshandiswa muindasitiri yemotokari, ichienderana nezvinodiwa zveVolkswagen zveVW50097 nePV6097. Mhedzisiro yekuyera ndeyechokwadi uye yakavimbika. Inonyanya kushandiswa pakuongorora porosity ye casting yealuminum alloys uye cast iron castings, uye yakakodzerawo pakuongorora porosity uye metallographic yezvimwe zvinhu.

Software yekuongorora mifananidzo ine porosity inogona kushandiswa nechikamu chemagetsi kuti ikwanise kuskena otomatiki, kutarisisa otomatiki, kusona otomatiki, kuyerwa otomatiki kweporosity, nhamba dzedata, uye kubuda kwemushumo.

Basa rekusona mufananidzo:Gadza maparamita ekusona uye rudzi rwemufananidzo, tinya "Auto Stitch," uye kusona mufananidzo kuchapedzwa otomatiki.

Zvirongwa zvema parameter ekutsvaga:Nekuisa nzvimbo diki, nzvimbo yepamusoro, uye chiyero, kutsvaga mepu yakazara kunogona kuitwa kuti uwane maburi ese ari mukati mezviyero zvakatarwa zvemepu yese.

Sarudzo yemufananidzo:Inopa maturusi ekusarudza akadai serectangle, polygon, denderedzwa, sikweya, uye triangle. Mushure mekunge sarudzo yapera, software inoongorora yega porosity panzvimbo yakasarudzwa.

Kuongorora maburi:Inogona kuongorora data rakadai se perimeter, area, major axis, minor axis, equivalent circle diameter, aspect ratio, uye roundness ye pore rega rega.

Kuyera kwejiyometri:Zvishandiso zvakasiyana-siyana zvekuyera zvinogona kushandiswa pakuenzanisa saizi

Nhamba dzedata uye kugadzirwa kwemishumo:Inogona kuongorora data rema parameter rakadzama repore rega rega uye kugadzira nzira mbiri dzemishumo, VW50093 kana VW50097.