Kodhi yekuomarara kwesimbi ndeye H. Zvichienderana nenzira dzakasiyana dzekuedza kuomarara, zviratidzo zvakajairika zvinosanganisira Brinell (HB), Rockwell (HRC), Vickers (HV), Leeb (HL), Shore (HS) kuomarara, nezvimwewo, pakati pazvo HB neHRC zvinonyanya kushandiswa. HB ine mhando dzakasiyana dzemashandisirwo, uye HRC yakakodzera zvinhu zvine kuomarara kwepamusoro, zvakaita sekuomarara kwekupisa. Musiyano ndewekuti indenter yemuyedzi wekuomarara yakasiyana. Brinell hardness tester iball indenter, nepo Rockwell hardness tester iri diamond indenter.

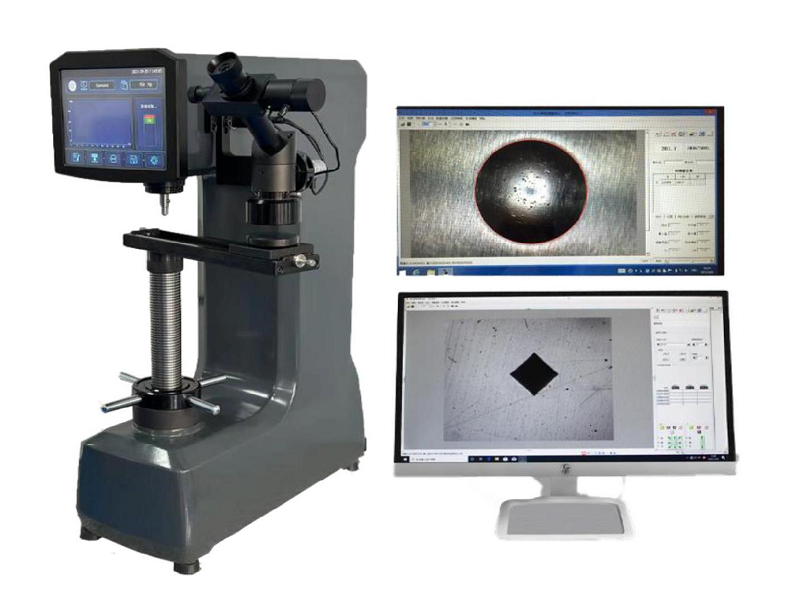

HV-yakakodzera kuongororwa kwemakroskopu. Vickers hardness (HV) Dhinda pamusoro pechinhu chacho nemutoro uri pasi pe120kg uye diamond square cone indenter ine vertex angle ye136°. Nzvimbo yepamusoro yegomba remukati mechinhu chacho yakakamurwa ne load value, inova Vickers hardness value (HV). Vickers hardness inoratidzwa seHV (tarisa GB/T4340-1999), uye inoyera sampuro dzakatetepa zvikuru.

Muchina wekuyedza kuomarara weHL unotakurika wakanakira kuyerwa. Unoshandisa musoro webhora rekurova kuti ubate pamusoro pesimba uye woburitsa bounce. Kuomarara kunoverengerwa nechiyero chekumhanya kwekudzoka kwepunch pa1mm kubva pamusoro pemuenzaniso kusvika pakumhanya kwekurova. Fomura yacho ndeiyi: Kuomarara kweLeeb HL=1000×VB (kumhanya kwekudzoka)/VA (kumhanya kwemhedzisiro).

Chinotakurika cheLeeb hardness tester chinogona kushandurwa kuita Brinell (HB), Rockwell (HRC), Vickers (HV), Shore (HS) hardness mushure mekuyerwa kweLeeb (HL). Kana kushandisa musimboti weLeeb kuyera zvakananga kukosha kwehardness neBrinell (HB), Rockwell (HRC), Vickers (HV), Leeb (HL), Shore (HS).

HB - Brinell kuomarara:

Kuomarara kweBrinell (HB) kunowanzo shandiswa kana zvinhu zvakapfava, zvakaita sesimbi dzisina simbi, simbi isati yapiswa kana mushure mekunamirwa. Kuomarara kweRockwell (HRC) kunowanzo shandiswa pazvinhu zvine kuomarara kwakanyanya, zvakaita sekuomarara mushure mekupiswa, nezvimwewo.

Kuomarara kweBrinell (HB) mutoro wekuyedza une saizi yakati. Bhora resimbi rakaomarara kana bhora rekabhoridhi rine dhayamita yakati rinodzvanywa pamusoro pesimbi kuti riedzwe. Mutoro wekuyedza unochengetwa kwenguva yakatarwa, uye mutoro unobviswa kuti upime dhayamita yekudzika pamusoro pemvura inofanira kuyedzwa. Kukosha kwekuomarara kweBrinell iquotient inowanikwa nekukamura mutoro nenzvimbo yedenderedzwa yedenderedzwa. Kazhinji, bhora resimbi rakaomarara rine saizi yakati (kazhinji 10mm mudhayamita) rinodzvanywa pamusoro pezvinhu zvine mutoro wakati (kazhinji 3000kg) uye rinochengetwa kwenguva yakati. Mushure mekunge mutoro wabviswa, chiyero chemutoro kunzvimbo yekudzika iBrinell hardness value (HB), uye unit i kilogram force/mm2 (N/mm2).

Kuomarara kweRockwell kunotarisa kukosha kwekuomarara zvichibva pahurefu hwepurasitiki hwekudzika kwemukati. 0.002 mm inoshandiswa seyuniti yekuomarara. Kana HB>450 kana sample iri diki, bvunzo yekuomarara yeBrinell haigone kushandiswa uye kuyerwa kwekuomarara kweRockwell kunoshandiswa panzvimbo payo. Inoshandisa koni yedhaimani ine kona ye120° kana bhora resimbi rine dhayamita ye1.59 kana 3.18mm kudzvanya pamusoro pechinhu chiri pasi pekuedzwa pasi pemutoro wakati, uye kuomarara kwechinhu kunoverengerwa kubva pahurefu hwekudzika. Zvichienderana nekuomarara kwechinhu chiri mukati, chinoratidzwa muzvikamu zvitatu zvakasiyana:

HRA: Ndihwo hunyoro hunowanikwa nekushandisa mutoro we60kg uye dhaimani cone indenter, iyo inoshandiswa pazvinhu zvine hunyoro hwakanyanya (senge simende carbide, nezvimwewo).

HRB: Ndihwo hunyoro hunowanikwa nekushandisa mutoro we100kg nebhora resimbi rakasimba rine dhayamita ye1.58mm, iro rinoshandiswa pazvinhu zvine hunyoro hwakaderera (senge simbi yakanyungudutswa, simbi yakakandwa, nezvimwewo).

HRC: Ndihwo hunyoro hunowanikwa nekushandisa mutoro we150kg uye dhaimani cone indenter, iyo inoshandiswa pazvinhu zvine hunyoro hwakanyanya (senge simbi yakaoma, nezvimwewo).

Pamusoro pe:

1.HRC zvinoreva kuomarara kweRockwell C scale.

2.HRC neHB zvinoshandiswa zvakanyanya mukugadzira.

3. HRC nzvimbo inoshanda HRC 20-67, yakaenzana neHB225-650,

Kana kuomarara kwacho kwakakwira kupfuura uku, shandisa Rockwell hardness A scale HRA,

Kana kuomarara kwacho kwakaderera pane uku, shandisa Rockwell hardness B scale HRB,

Muganho wepamusoro wekuomarara kweBrinell iHB650, iyo isingakwanise kuva yakakwira kupfuura kukosha uku.

4. Chiyero cheC hardness tester cheRockwell idhaimani ine kona ye vertex ye 120 degrees. Mutoro wekuyedza une kukosha kwakati. Chiyero cheChinese i 150 kgf. Chiyero cheBrinell hardness tester ibhora resimbi rakaomarara (HBS) kana bhora re carbide (HBW). Mutoro wekuyedza unosiyana zvichienderana nedhayamita yebhora, kubva pa 3000 kusvika 31.25 kgf.

5. Kudzika kwehukobvu hweRockwell kudiki kwazvo, uye kukosha kwakayerwa kunowanikwa munzvimbo. Zvakakosha kuyera mapoinzi akati wandei kuti uwane avhareji yehuwandu. Yakakodzera zvigadzirwa zvakapedzwa uye zvidimbu zvitete uye inoiswa muchikamu chekuyedza kusingaparadze. Kudzika kwehukobvu hweBrinell kwakakura, kukosha kwakayerwa kwakarurama, haina kukodzera zvigadzirwa zvakapedzwa uye zvidimbu zvitete, uye kazhinji haiiswe muchikamu chekuyedza kusingaparadze.

6. Kukosha kwekuomarara kweRockwell inhamba isina mazita isina mayuniti. (Saka, hazvina kunaka kudana Rockwell kuti kuomarara sedanho rakati.) Kukosha kwekuomarara kweBrinell kune mayuniti uye kune hukama hwakati hwepedyo nekusimba kwekusimba.

7. Kuomarara kweRockwell kunoratidzwa zvakananga padhayari kana kuratidzwa nedhijitari. Zviri nyore kushandisa, zvinokurumidza uye zviri nyore kushandisa, uye zvakakodzera kugadzirwa nevanhu vakawanda. Kuomarara kweBrinell kunoda maikorosikopu kuti uedze dhayamita yekupinda mukati, wobva watarisa patafura kana kuverenga, izvo zvinonetsa kushandisa.

8. Mune mamwe mamiriro ezvinhu, HB neHRC zvinogona kuchinjaniswa nekutarisa patafura. Fomura yekuverenga yepfungwa inogona kunyorwa se: 1HRC≈1/10HB.

Kuedza kuomarara inzira iri nyore uye iri nyore yekuyedza mukuyedza hunhu hwemakanika. Kuti ushandise bvunzo yekuomarara kutsiva mimwe miedzo yehunhu hwemakanika, hukama hwakarurama hwekushandura pakati pekuomarara nesimba hunodiwa mukugadzirwa.

Kudzidzira kwakaratidza kuti pane hukama hunoenderana pakati pemhando dzakasiyana dzehukukutu hwesimbi uye pakati pehukukutu uye hukoshi hwesimba. Nekuti hukoshi hwehukukutu hunotsanangurwa nekuramba kwekutanga kwekuchinja kwepurasitiki uye kuramba kuripo kwekuchinja kwepurasitiki, simba rechinhu chacho rakakwirira, kuramba kuripo kwekuchinja kwepurasitiki kwakakwira, uye kukosha kwekuoma kwakakwira.

Nguva yekutumira: Nyamavhuvhu-16-2024