Kune mhando dzakawanda dzesimbi dzinopfekwa. Mapendi akasiyana anoda simba rekuyedza rakasiyana mukuyedza kuomarara kwe microhardness, uye simba rekuyedza harigone kushandiswa zvisina tsarukano. Pane kudaro, bvunzo dzinofanirwa kuitwa zvichienderana nezvinodiwa nesimba rekuyedza zvinokurudzirwa nezvinodiwa. Nhasi, tichanyanya kuunza bvunzo dze micro Vickers dzekuomarara kwe zinc coatings kana zinc-aluminium-magnesium alloy coatings dzinoshandiswa pasimbi.

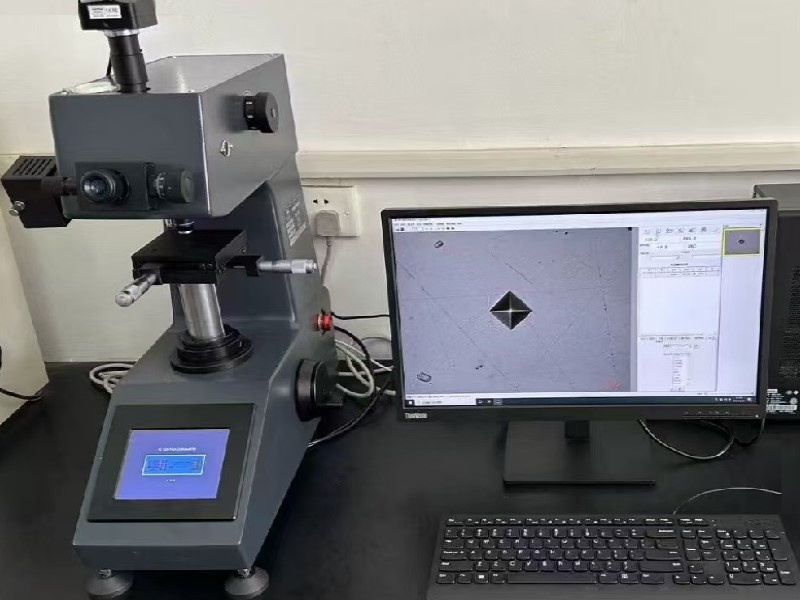

1. Kugadzirira sampuro dzemhando yepamusoro dzesimbi dzezinc coatings (kana aruminiyamu-magnesium coatings) ndiyo nhanho yekutanga mukuyedza coatings. Kugadzirira sampuro dzezinc coatings kunosanganisira matanho akawanda, anosanganisira sampuro, kuisa, uye kukuya nekupukuta. Chinangwa chekugadzirira sampuro dzakadaro ndechekukuya pamusoro pechinhu chebasa kuita nzvimbo yakatsetseka, yakati sandara inobvumira kuona zvakajeka Vickers indentations, zvichiita kuti kuyerwa kwakarurama kwehukuru hwe indentations kuti kuwane kukosha kwekuoma.

2.Kuti zviome zvekuomeswa kwe zinc: sezvo zinc coatings dzakakora, bvunzo dzekuoma dzinogona kuitwa nemasimba akasiyana ekuyedza. Pamuenzaniso mumwe chete, simba rekuyedza rinoshandiswa diki, saizi yekudzika kwebvudzi idiki; zvakasiyana, simba rekuyedza rakakura, saizi yekudzika kwebvudzi ikuru. Kana chifukidziro chakatenderedza chikaratidza zviratidzo zvekutsemuka kana kuchinjika, simba diki rekuyedza rinofanira kusarudzwa. Maitiro aya anodzokororwa kusvika chifukidziro chakatenderedza Vickers chikaramba chakasimba pasina kuchinjika—danho iri resimba rekuyedza ndiro rakakodzera muenzaniso.

2.1 Ukobvu hwakasiyana hwekuputira hunoenderana nehuwandu hwesimba rekuyedza, izvo zvakakosha kudzivirira kukanganisa kwemhedzisiro yekuyedza. Izvi zvinotevera ireferensi yekusarudzwa kwesimba rekuyedza kune machira akajairika (zinc plating, chromium plating), inoshanda kune vanoedza kuomarara kwe micro Vickers (HV):

| Rudzi rwekuputira | Kuputira Ukobvu (μm) | Kurudzira Simba rekuyedza (gf) | Inoenderana Chikero cheHV | Zvinokosha Zvekudzivirira |

| Zingi Kuisa jira | 5 ~ 15 | 25 ~ 50 | HV0.025, HV0.05 | Kuisa zinc plating kwakapfava (kazhinji HV50~150); simba diki rinodzivirira kupinda mukati zvakanyanya. |

| Zingi Kuisa jira | 15 ~ 50 | 50 ~ 100 | HV0.05, HV0.1 | Sezvo ukobvu huchiwedzera, simba rinogona kusimudzwa zvakakodzera kuitira kuti mipendero yekudzika ive pachena. |

| Chromium Kuisa jira | 1 ~ 5 | 10 ~ 25 | HV0.01, HV0.025 | Chromium yakaoma (HV800~1200) ine kuomarara kwakanyanya; simba diki rinodzivirira kukuvara kwemukati meganda. |

| Chromium Kuisa jira | 5 ~ 20 | 25 ~ 100 | HV0.025, HV0.1 | Kana ukobvu hwacho hwasvika >10μm, HV0.1force inoenzanisa kururama uye kushanda zvakanaka. |

| Chinhu chakasanganiswa Kuputira | <5 | ≤25 | HV0.01, HV0.025 | Pamachira akaita se zinc-nickel alloy uye chromium-nickel alloy, dzivirirai kuti kupinda mukati mejira kurege kupinda mukati. |

2.2 Zvimwe Zvinhu Zvikuru Zvinopesvedzera Kuchinja Kwemamiriro Ezvinhu

Pamusoro pekukora, zvinhu zviviri zvinotevera zvichachinja zvakanyanya kusarudzwa kwesimba rekuyedza, uye zvinofanirwa kutonga zvichibva pane zvakaitika chaizvo:

Kubata Kuoma Kwemhando:

Kupfeka kwakapfava (semuenzaniso, zinc plating, HV <200): Kana simba rekuyedza riri diki, maburi anogona kusviba nekuda kwekuchinja kwepurasitiki kwejira. Zvinokurudzirwa kusarudza muganho wepamusoro werudzi rwunokurudzirwa (sekuti., ukobvu 10 μm, sarudza simba rekuyedza re50gf).

Kupfeka kwakasimba (semuenzaniso, chromium plating, HV > 800): Kuomarara kwakanyanya kunoita kuti pave nekukasira kudiki, saka simba rekuyedza harifanirwe kunge diki zvakanyanya (sekukora 5 μm, sarudza simba rekuyedza re25gf) kudzivirira kukanganisa kwekuyera kwe diagonal yekukasira kusingapfuure ± 5%.

2.3 Zvinodiwa zveMaitiro neMagadzirirwo

Maindasitiri akasiyana ane mitemo yakajeka. Semuenzaniso:

Indasitiri yemotokari inowanzo tora ISO 14577 (Instrumented Indentation Test), iyo inobvumira kugadzirisa simba remagetsi zvichienderana nehukobvu hwekuputira;

Indasitiri yemazuva ano inoreva ASTM E384, iyo inoda kuti diagonal ye indentation ive ≤ 1/2 yeukobvu hwe coating uye ≥ kagumi kupfuura radius ye indenter tip (kudzivirira mhedzisiro ye tip).

Mukupedzisa, kusarudzwa kwesimba rekuyedza bvunzo dzesimbi dze micro-Vickers kunofanira kutevedzera pfungwa yekuti "kutanga ukobvu, kugadzirisa kuomarara, uye vimbiso yakajairika":

Kutanga, sarudza huwandu hwesimba rekuyedza zvichibva pakukora kwejira (tarisa tafura iri pamusoro);

Gadzirisa kukosha kwesimba zvichienderana nekuoma kwejira (sarudza muganho wepamusoro wejira rakapfava uye muganho wepasi wejira rakaoma);

Chekupedzisira, tevedzera mitemo yeindasitiri (yakadai seISO 14577 neASTM E384) kuti uve nechokwadi chekuti mhinduro dzebvunzo dzakarurama.

Nguva yekutumira: Gunyana-03-2025