Kune vatengi vazhinji vane zvinodiwa zvakanyanya kuti vanyatsoongorora kuomarara, kuenzaniswa kwevaongorori vesimba rekusimbisa kunowedzera kudiwa kwakanyanya pamatanho ekusimbarara. Nhasi, ndinofara kuunza nhevedzano yematanho ekusimbaradza eClass A.—Matanda ekusimbaradza eRockwell, Matanda ekusimbaradza eVickers, Matanda ekusimbaradza eBrinell, HRA, HRB, HRC, HRE HRR, HV, HBW nezvimwewo.

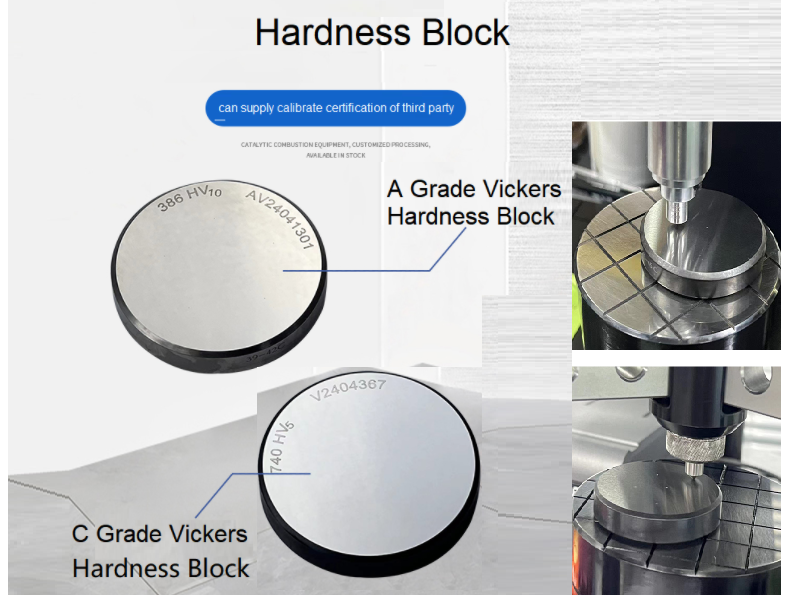

Mabhuroko emhando yeA hardness blocks anofanirwa kutevedzera mitemo yakaoma yekugadzirisa, kugadzirisa pamusoro pechinhu, uye kupisa. Maitiro ekugadzira mabhuroko aya ehardness anosanganisira nzira dzepamusoro dzekugadzira. Nzvimbo dzeCNC dzekugadzira michina dzemazuva ano dzinoshandiswa kuona kuti saizi yemabhuroko ehardness inosangana nezvinodiwa chaizvo. Paramita yega yega yekucheka inogadziriswa nokungwarira kuderedza chero zvikanganiso zvinogona kuitika.

Pakugadzirisa pamusoro, nzira dzakasiyana dzekupedzisa pamusoro dzinoshandiswa. Kupukuta nemakemikari uye kurongedza nemazvo kunoitwa kuti pave nechinhu chisina kusimba zvakanyanya. Izvi hazvingoderedzi chete kukanganiswa kwekusagadzikana kwepamusoro panguva yekuyera kuomarara asi zvinowedzerawo kunamira pakati pechinhu chinoyera kuomarara nechepamusoro pechinhu chinovhara kuomarara, zvichiita kuti pave nemhedzisiro chaiyo yekuyera.

Maitiro ekurapa kupisa eClass A hardness blocks anodzorwawo zvine hungwaru. Maovheni epamusoro ekurapa kupisa ane masisitimu ekudzora tembiricha chaiwo anoshandiswa. Munguva yekurapa kupisa, mwero wekupisa, nguva yekubata, uye mwero wekutonhodza zvese zvinodzorwa zvakasimba zvichienderana ne process curve chaiyo. Izvi zvinoita kuti chimiro chemukati chehardness block chive chakafanana uye chakagadzikana, zvichideredza zvinobudirira kushushikana kwemukati mukati mechinhu chacho.

Nekuda kwemaitiro aya akaomarara, kusava nechokwadi kwekuyera ma hardness blocks eClass A kwakadzikira zvakanyanya, uye kufanana kwawo kwakakwira zvakanyanya kana tichienzanisa nedzimwe mhando dzehardness blocks. Anopa hwaro hwakavimbika hwekuyera ma hardness testers, zvichiita kuti ma hardness testers awane kunyatsojeka uye kugadzikana mukuyera kwavo. Ingave mukugadzirwa kwemaindasitiri, kudzora mhando mumarabhoritari, kana minda yekutsvagisa kwesainzi, ma hardness blocks eClass A anoita basa rinokosha uye rakakosha, achibatsira nyanzvi kuwana data rakarurama uye rakavimbika rekuyera hardness.

Nekusarudza maburi ekuomarara eClass A, vatengi vanogona kuva nechivimbo chakazara mukuongororwa kwevayedzisi vavo vekuomarara, vachiona kuti mhedzisiro yavo yekuyedza kuomarara yakarurama uye inowirirana, uye nokudaro vachipa rutsigiro rwakasimba rwekudzora mhando uye kugadzirwa kwechigadzirwa chezvigadzirwa zvavo.

Nguva yekutumira: Kurume-10-2025