1 Kugadzirira usati waedzwa

1) Chiyedzo chehukukutu nechinhu chinoshandiswa pakuongorora hukukutu hweVickers chinofanira kutevedzera zvinodiwa neGB/T4340.2;

2) Tembiricha yemukamuri inofanira kudzorwa mukati me10~35℃. Pakuyedzwa kwakanyatsojeka, inofanira kudzorwa pa (23±5)℃.

Mienzaniso miviri

1) Nzvimbo yemuenzaniso inofanira kunge yakati sandara uye yakapfava. Zvinokurudzirwa kuti nzvimbo yemuenzaniso inofanira kusangana nezvinodiwa: Kukosha kukuru kweparameter yenzvimbo yekuomarara: Muenzaniso wekuomarara weVickers 0.4 (Ra)/μm; muenzaniso wekuomarara weVickers 0.2 (Ra)/μm; muenzaniso wekuomarara weVickers 0.1 (Ra)/μm

2) Kune sampuli dzeVickers nemicro Vickers dzine mutoro mudiki, zvinokurudzirwa kusarudza kupolisha kwakakodzera uye kupolisha kwemagetsi kuti zvishandiswe pakugadzirisa pamusoro zvichienderana nerudzi rwechinhu chacho.

3) Ukobvu hwemuenzaniso kana jira rekuyera hunofanira kunge hwakapetwa ka1.5 kupfuura urefu hwe diagonal hwe indentation

4) Pakushandisa diki diki uye micro Vickers pakuedza, kana sampuli iri diki kwazvo kana kuti isina kurongeka, sampuli inofanira kuiswa mukati kana kusungirirwa nechinhu chakakosha usati waedza.

3Nzira yekuedza

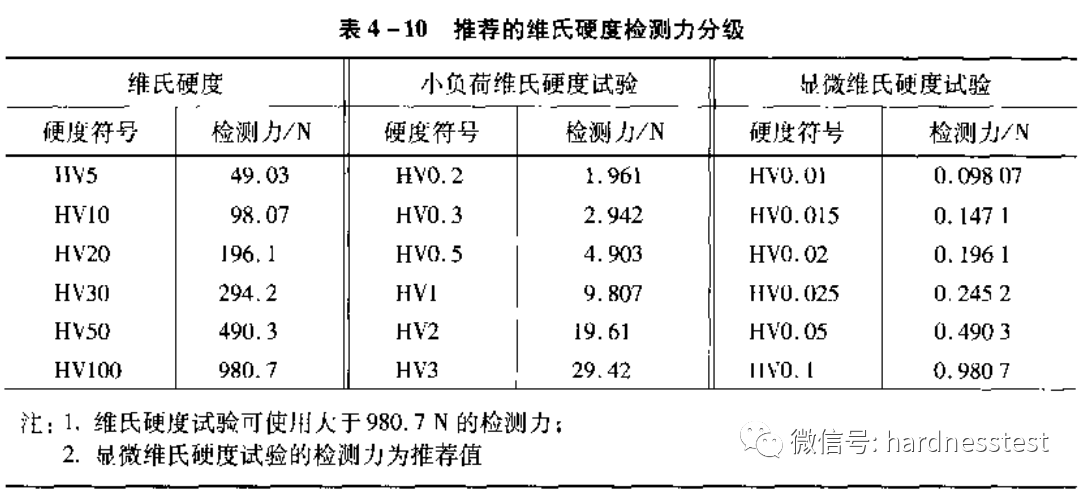

1) Kusarudzwa kwesimba rekuyedza: Zvichienderana nekuoma, ukobvu, saizi, nezvimwewo zvemuenzaniso, simba rekuyedza rinoratidzwa muTafura 4-10 rinofanira kusarudzwa kuti riitwe bvunzo.

2) Nguva yekushandisa simba rekuyedza: Nguva kubva pakutanga kwekushandisa simba kusvika pakupedzwa kwekushandisa simba rekuyedza rose inofanira kunge iri mukati memasekondi maviri kusvika gumi. Kune bvunzo dzeVickers dzine mutoro mudiki uye micro Vickers, kumhanya kwekudzika kwe indenter hakufanirwe kudarika 0.2 mm/s. Nguva yekubata simba rekuyedza imasekondi gumi kusvika gumi nemashanu. Kune zvinhu zvakapfava zvakanyanya, nguva yekubata inogona kuwedzerwa, asi kukanganisa kunofanira kunge kuri mukati memasekondi maviri.

3) Kureba kubva pakati pechinongedzo kusvika kumucheto wemuenzaniso: Simbi, mhangura nemhangura alloys zvinofanira kunge zvakapetwa kaviri nehafu pakureba kwediagonal yeinongedzo; simbi dzakareruka, lead, tin ne alloys dzadzo zvinofanira kunge zvakapetwa katatu pakureba kwediagonal yeinongedzo. Kureba kuri pakati penzvimbo mbiri dziri pedyo: kune simbi, mhangura nemhangura alloys, inofanira kunge yakapetwa katatu pakureba kwemutsetse wediagonal wechiratidzo chekumira; kune simbi dzakareruka, lead, tin ne alloys dzadzo, inofanira kunge yakapetwa katanhatu pakureba kwemutsetse wediagonal weinongedzo.

4) Yera avhareji yemasvomhu ehurefu hwema diagonals maviri e indentation, uye tsvaga kukosha kwehukukutu hweVickers zvichienderana netafura, kana kuverenga kukosha kwehukukutu zvichienderana nefomura.

Musiyano uripo pakureba kwemadiagonal maviri ekudzika kwenzvimbo iri mudenga haufanirwe kudarika 5% yeavhareji yehukuru hwediagonal. Kana ikapfuura, inofanira kunyorwa mumushumo wekuyedza.

5) Pakuyedza pane sampuli yepamusoro yakakombama, mhedzisiro yacho inofanira kugadziriswa zvichienderana netafura.

6) Kazhinji, zvinokurudzirwa kutaura nezvehunhu hwebvunzo yekuoma kwebvunzo hwemapoinzi matatu pamuenzaniso wega wega.

4 Kurongwa kweVickers kuomarara

Kune mhando mbiri dzezviyedzo zveVickers zvinoshandisa simba. Izvi zvinotevera ndiwo mashandisirwo anowanzoitwa Vickers hardness tester:

1. Rudzi rwekuyera ziso;

2. Rudzi rwekuyera software

Kurongwa 1: Rudzi rwekuyera ziso Rudzi rwezvinhu: Shandisa ziso kuyera. Mashandisirwo: Muchina unogadzira (dhaimani ◆) indentation, uye kureba kwedhaimani kunoyerwa ne dinamu yedhaimani kuti uwane kukosha kwekuoma.

Kupatsanurwa 2: Rudzi rwekuyera software: Zvinhu: Shandisa software yekuomarara kuyera; iri nyore uye iri nyore pamaziso; inogona kuyera kuomarara, kureba, kuchengetedza mifananidzo yekuomarara, mishumo yenyaya, nezvimwewo. Mashandisirwo: Muchina unogadzira (dhaimani ◆) indentation, uye kamera yedhijitari inounganidza indentation pakombiyuta, uye kukosha kwekuomarara kunoyerwa pakombiyuta.

5Kupatsanura Software: 4 shanduro dzekutanga, shanduro yekudzora turret otomatiki, shanduro ye semi-otomatiki, uye shanduro ye otomatiki zvizere.

1. Shanduro yekutanga

Inogona kuyera kuomarara, kureba, kuchengetedza mifananidzo yekudzika, mishumo yenyaya, nezvimwewo;

2.Software yekushandura otomatiki ye turret inogona kudzora turret yekuedza kuomarara, senge, lenzi yekutarisa, indenter, kurodha, nezvimwewo;

3. Shanduro yeSemi-otomatiki ine tafura yekuedza yemagetsi yeXY, bhokisi rekudzora repuratifomu re2D; Kuwedzera kune basa reshanduro ye automatic turret, software inogonawo kugadzirisa nzvimbo nenzvimbo, otomatiki dotting, otomatiki kuyerwa, nezvimwewo;

4. Shanduro inogadzirwa otomatiki ine tafura yekuedza yemagetsi yeXY, bhokisi rekudzora re3D platform, Z-axis focus; Kuwedzera kune semi-automatic version function, software iyi inewo Z-axis focus function;

6Maitiro ekusarudza mudziyo wekuedza kuomarara weVickers wakakodzera

Mutengo weVickers hardness tester uchasiyana zvichienderana nemagadzirirwo uye mashandiro ayo.

1. Kana uchida kusarudza yakachipa, unogona kusarudza:

Midziyo ine skrini diki yeLCD uye nzira yekuisa nemaoko kuburikidza ne eyepiece;

2. Kana uchida kusarudza mudziyo usingadhuri, unogona kusarudza:

Midziyo ine LCD screen hombe, eyepiece ine digital encoder, uye printer yakavakirwa mukati;

3. Kana uchida mudziyo wepamusoro-soro, unogona kusarudza:

Midziyo ine touch screen, sensor yeclosed-loop, eyepiece ine printer (kana USB flash drive), screw yekusimudza giya reworm, uye digital encoder;

4. Kana uchifunga kuti zvinonetesa kuyera nechinhu chinovhara ziso, unogona kusarudza:

Yakashongedzerwa neCCD hardness image processing system, inoyera pakombuta usingatarise eyepiece, iyo iri nyore kushandisa, inokurumidza uye iri nyore kushandisa. Unogona zvakare kugadzira mishumo uye kuchengetedza mifananidzo inopinza, nezvimwewo.

5. Kana uchida kushanda zviri nyore uye otomatiki yakawanda, unogona kusarudza:

Muedzi wekusimbisa kuomarara weVickers otomatiki uye muedzi wekusimbisa kuomarara weVickers otomatiki zvizere

Zvinhu: sarudza nzvimbo nenzvimbo dzemapoinzi, wobva wanyora otomatiki uye nguva dzose, wozoyera otomatiki.

Nguva yekutumira: Gumiguru-17-2024