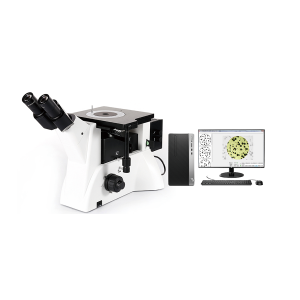

Maikorosikopu yekuyera kupinda kweSC-2000C Welding

Maikorosikopu yekuona kupinda kwesimbi yeWelding 2000C ine maikorosikopu yepamusoro-soro uye software yekuyera kupinda kwesimbi, iyo inogona kuyera nekuchengetedza mifananidzo yekupinda kwesimbi inogadzirwa nezvikamu zvakasiyana-siyana zvewelding (majoini emapato, majoini emakona, majoini emakumbo, majoini ane chimiro cheT, nezvimwewo). Panguva imwe chete, kuongororwa kwehukuru hwewelding kunogonawo kuitwa, uye maikorosikopu maviri anopihwa kuti aongorore kunaka kwewelding. Kupinda kwesimbi yeWelding kunoreva kudzika kwekunyunguduka kwesimbi yebase. Panguva yewelding, panofanira kunge paine kupinda kwakati kuti simbi mbiri dzebase dzibatanidzwe pamwe chete. Kusapinda kwakakwana kunogona kukonzera nyore nyore welding isina kukwana, slag inclusions, weld nodules uye cold Cracks nezvimwe zvinetso. Kupinda kwakadzika zvakanyanya kunogona kukonzera burn-through, undercut, pores nezvimwe zviitiko, izvo zvinokanganisa zvakananga kunaka kwewelding. Saka, zvakakosha zvikuru kuyera kupinda kwesimbi yeWelding. Mumakore achangopfuura, nekukura nekukurumidza kwetekinoroji dzemazuva ano dzakadai semagetsi, makemikari, simba reatomu, mota, kuvaka ngarava, uye aerospace, maindasitiri akasiyana-siyana ane zvinodiwa zvakanyanya zvemhando yewelding, uye kuonekwa kwemhando yewelding kwakakosha pakuvandudza maindasitiri eindasitiri yekugadzira michina. Zvakakosha. Kuvandudzwa kwemainjini ekupinda kwemainjini kuri pedyo. Mukupindura mamiriro ezvinhu aya, takagadzira nekugadzira maikorosikopu HB5276-1984 yearuminiyamu alloy resistance spot welding iyo inoyera kupinda kwemainjini zvichienderana nezvinodiwa muinjini (HB5282-1984 Structural steel and stainless steel resistance spot welding and seam welding quality inspection). uye seam welding quality inspection) welding quality inspection system 2000C. Iyi sisitimu haingogone kuyera kupinda kwemainjini chete (tichishandisa nzira yekuparadza) asiwo kutarisa kunaka kwemainjini, kuona mitswe, maburi, uneven welds, slag inclusions, pores uye ma dimensions akafanana, nezvimwewo. Kuongororwa kweMacroscopic.

- Chimiro chakanaka, mashandiro anochinjika, resolution yepamusoro uye mifananidzo yakajeka

- Kudzika kwekupinda kunogona kuonekwa nemazvo, scale bar inogona kuiswa pamusoro pemufananidzo wekupinda, uye zvinobuda zvinogona kuchengetedzwa.

- Kuongororwa kwesimbi dzesimbi dzemacroscopic nekuongororwa kwewelding kunogona kuitwa, zvakaita sekuti: kana paine maburi, slag inclusions, cracks, kushaya penetration, kushaya fusion, undercuts nezvimwe zvikanganiso munzvimbo yeweld kana nzvimbo ine kupisa.

GreenoughAngle yekubatana kwemadhigirii gumi mu optical system inoita kuti mufananidzo uve wakadzikama zvakanaka pasi pemunda wakakura. Kusarudza nekungwarira magirazi ekugadzira magirazi e optical system yese kunogona kukonzera kuona kwemavara chaiwo uye kurekodha sampuli. Nzira ye optical yakaita seV inobvumira muviri we zoom mutete, uyo wakakodzera kubatanidzwa mune zvimwe zvishandiso kana kushandiswa wega.

Chiyero cheM-61 che6.7:1 zoom ratio chinowedzera kukura kubva pa6.7x kusvika pa45x (kana uchishandisa eyepiece ye10x) uye chinoita kuti macro-micro zoom iite zvakanaka kuti ikurumidze kushanda kwese kwese.

Kona yemukati chaiyo inopa musanganiswa wakakwana wekuti nzvimbo yacho yakati sandara uye yakadzika kuti ionekwe ne3D. Kunyangwe sampuli dzakakora dzinogona kutariswa kubva kumusoro kusvika pasi kuti dziongororwe nekukurumidza.

Daro rakakura rekushanda

Kureba kwekushanda kwe110mm kunoita kuti zvive nyore kutora, kuisa uye kushanda kwemuenzaniso.

SC-2000C inoshandisa 0.67X, 0.8X, 1.0X, 1.2X, 1.5X, 2.0X, 2.5X, 3.0X, 3.5X, 4.0X, 4.5X, 11 magiya ekuwedzera, ayo anogona kugadzirisa nemazvo kukura kwakagadzika. Inopa chinodiwa kuti uwane mhedzisiro yekuyera yakafanana uye yakarurama.

| Muenzaniso | Maikorosikopu yekuyera kupinda kweSC-2000C Welding |

| Kukwidziridzwa kwakajairika | 20X-135X |

| Kukwidziridza kwesarudzo | 10X-270X |

| lenzi isina chinangwa | 0.67X-4.5X zoom inoenderera mberi, chiyero che zoom ye lenzi chaiyo 6.4:1 |

| sensor | 1/1.8”COMS |

| chisarudzo | 30FPS@3072×2048 (mamiriyoni 6.3) |

| Chinobuda chinobuda | USB3.0 |

| Software | Software yekuongorora kupinda kwewelding yehunyanzvi. |

| Basa | Kutarisa panguva chaiyo, kutora mifananidzo, kurekodha mavhidhiyo, kuyerwa, kuchengetwa, kuburitswa kwedata, uye kubuda kwemushumo |

| puratifomu yenharembozha | Rudzi rwekufamba: 75mm*45mm (sarudzo) |

| Saizi yemonita | kureba kwekushanda100mm |

| bhureki repasi | Chikomboredzo cheruoko rwekusimudza |

| kuvhenekesa | Mwenje we LED unogadziriswa |

| Kugadzirisa komputa | Dell (DELL) OptiPlex 3080MT operating system W10 processor chip I5-10505, 3.20GHz memory 8G, hard drive 1TB, (sarudzo) |

| Dell monitor ine 23.8 inch HDMI high definition 1920*1080 (sarudzo) | |

| magetsi | Adapta yemagetsi yakafara yekunze, inopinza 100V-240V-AC50/60HZ, inoburitsa DC12V2A |